Difference between QMS and ERP: Key Aspects and Functionalities

Comparing QMS Software (Quality Management System) and ERP Software (Enterprise Resource Planning) is akin to contrasting apples and oranges. Both fall into the broader category of business software, yet their functions and importance diverge significantly, crucially enhancing businesses by streamlining operations in different ways.

Discover more about their unique capabilities, distinct features, and interconnectedness. The surprising conclusion might reveal an unexpected synergy between these two essential systems. Keep reading to explore their differences and their surprising connection!

Overview:

Businesses of all sizes and types can use QMS and ERP software. QMS software is crucial for companies that operate in highly regulated environments such as healthcare, aerospace and defense, the automobile industry, food and beverage industry, etc. Since these organizations typically have to abide by quality standards and rules like ISO 9001, they require a software solution to monitor and record their quality processes.

On the other side, businesses of various sizes, industries, and sorts need ERP to automate and streamline their operational procedures from start to finish along the complete supply chain. ERP software can help businesses make better decisions, and boost productivity and profitability to have a unified perspective of their business operations.

However, businesses often get confused if they should implement an enterprise resource planning system or deploy a standalone quality management system. As the features of these systems frequently overlap, there may be discussions among companies who have already implemented both systems over which system best meets a certain functional requirement.

But the key is, when it’s about managing the processes of regulated industries, it’s important for manufacturers to deploy a solution that can oversee quality and is also suitable for their regular business operations, procedures, and outputs. It should be a blend of the quality and their supply chain functionalities.

What is a QMS?

A formalized system that documents processes, procedures and responsibilities for carrying out quality policies and objectives is known as a quality management system (QMS). A QMS helps in organizing and directing an organization’s operations to satisfy the customer and regulatory requirements and continuously enhance effectiveness and efficiency.

Benefits of QMS:

- Streamline and automate end-to-end business operations

- Centralize data for a single source of truth

- Rapid responses to critical business issues

- Gain comprehensive business insights

- Accelerate company and financial reporting processes

- Ensure compliance with legal requirements through enhanced visibility

- Unified platform for data storage and integration with shared databases

- Optimize stock levels and inventory management

- Efficient warehouse management to support operations

What is ERP?

Enterprise resource planning (ERP) is a modular business management software that organizations use to manage day-to-day business activities such as accounting, procurement, project management, human resources, compliance, and supply chain operations, etc. A complete ERP software suite includes enterprise performance management, planning, budgeting, predicting, and reporting on an organization’s financial health.

ERP systems allow for the exchange of data between various business processes and bind them all together. They avoid data redundancy and ensure data integrity with a single source of truth by gathering an organization’s shared transactional data from several sources. The new-gen ERPs are available on different platforms- cloud ERP, on-premise ERP, and hybrid ERP.

Benefits of ERP:

- End-to-End Process Optimization: Streamline operations from start to finish

- Unified Data Repository: Obtain a reliable single source of truth

- Rapid Decision-Making: Prompt responses to critical business issues

- Comprehensive Analytics: Deeper insights for informed decisions

- Accelerated Reporting: Expedite company and financial reporting

- Enhanced Compliance: Maximize visibility to meet legal requirements

- Centralized Data Platform: Single platform for data storage and integration

- Optimized Inventory: Improved stock levels and control

- Efficient Warehousing: Streamline warehouse management operations

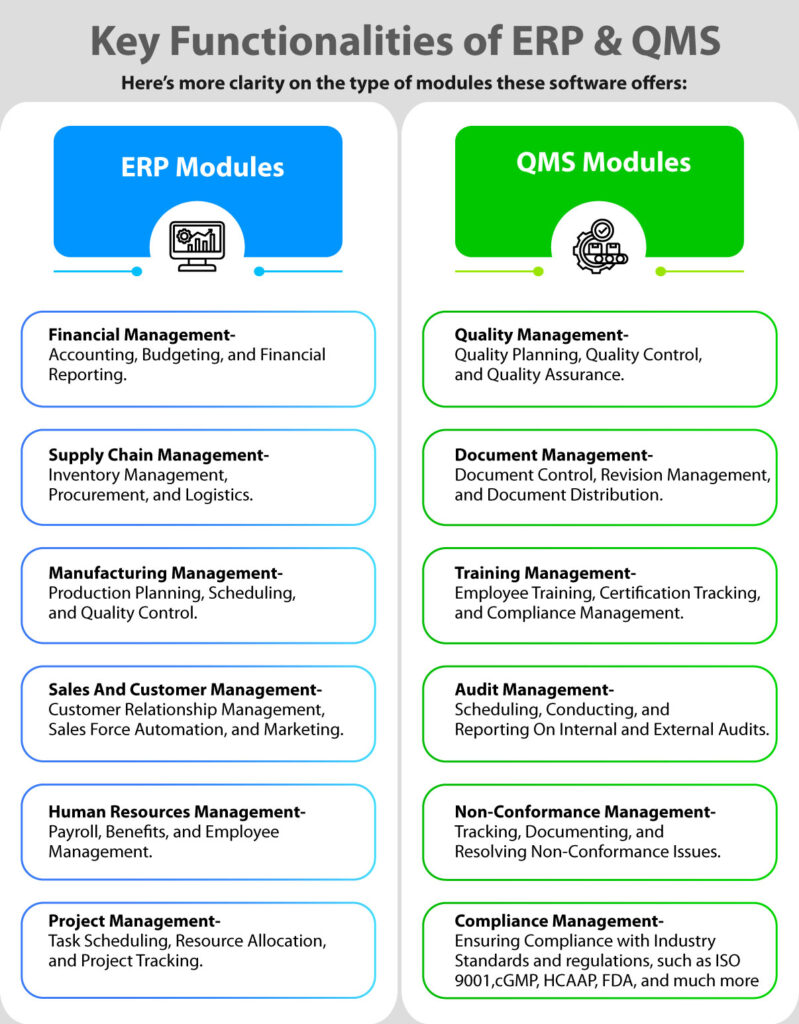

Key Functionalities of ERP & QMS:

Here’s more clarity on the type of modules these software offers:

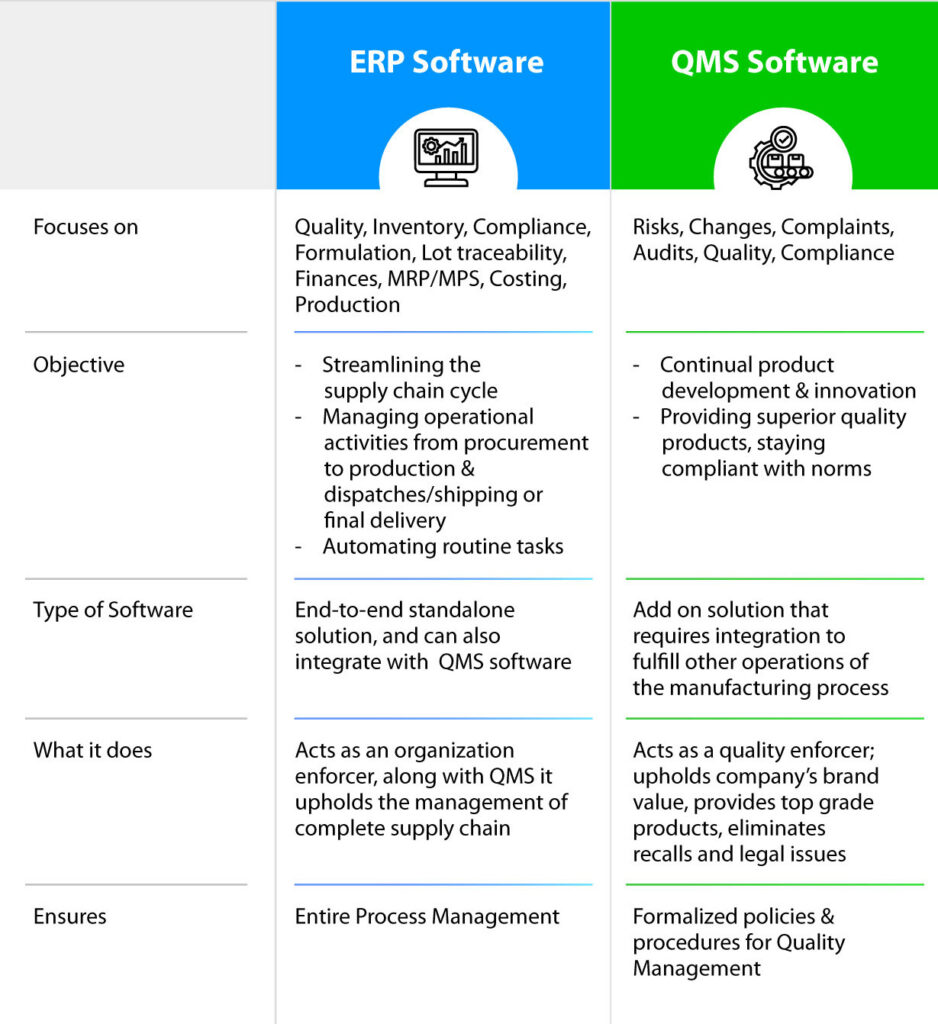

Difference Between ERP and QMS

The Potential of Combining QMS & ERP

Disparate systems and quality control procedures can rapidly silo crucial enterprise as well as quality data, resulting in complexity, limiting visibility and standards, both inside and between the facilities.

An ERP solution can enable enterprise integration and meet a variety of manufacturing needs. And a QMS can ensure quality at each step. However, adoption of integration of an ERP system and a QMS, will make it possible for the two systems to communicate with one another and exchange data, seamlessly, reducing duplication and delays associated with manual upload and download.

And so, to compete, expand, and innovate, manufacturers should adopt a cloud-based enterprise resource planning system with quality management features.

- Integrating the two softwares can help businesses automate quality workflows into operational processes resulting in thorough application of quality processes across the entire supply chain cycle.

- Improvement in quality and compliance drives the ability to standardize, streamline and simplify processes.

- Businesses can predict trends and risks on the company by analyzing real-time data stored centrally which will drive them towards continuous improvement.

- By automating quality procedures, it becomes possible to promote and apply best cGMP practices in all operations that enhances the quality of the final output.

- QMS and ERP together speed audits and keep manufacturers away from legal obligations and fines without compromising on quality.

- Streamlining workflows and synchronizing them between quality and manufacturing reduces cycle times, throughput value and resource requirements.

Combining a QMS and ERP system can result in improved data accuracy, better collaboration, increased efficiency, enhanced visibility, and improved compliance. By leveraging these benefits, manufacturers can drive performance improvements, respond more quickly to changing market conditions, focus on innovation, preserve capital and remain competitive in a rapidly evolving industry.

Summarizing thoughts

Understanding the needs of the business and all the associated functional groups is essential to choose the best solution. In light of the needs of the business, the capabilities of the various systems must be assessed.

The focus should be on the actual demands of the business rather than personal preferences or previous experiences. It’s crucial to determine and document the needs of each functional group participating in the business process, and to obtain their explicit agreement that this document fully and accurately satisfies those demands.

The true capabilities of both systems can be evaluated through research and vendor demos. With a clear understanding of the capabilities of each system, companies can weigh the pros and cons of various approaches.

It is critically important that all the individuals involved strive to be objective and reach consensus across all functional groups. So, it completely depends on the need of businesses that they want to integrate the system or want to use it as a standalone.

If you still have any questions about it, we would be pleased to help. Contact us by sending an email at sales@tecwrk.com with any questions or requests for a demo.